| Product | Ringlock System Scaffold |

| Material | Q235 Q345 |

| Surface | Hot Dipped Galvanized |

| Standard |

EN12811 |

|

Package |

Steel Pallet |

Product Introduction

Ringlock System Scaffold is a modular system consists of Standard, Ledger, Diagonal Brace, Brackets and steel planks, etc. The wedge-Rosette connectors are tried and tested to be a high efficient connection compared with conventional system

Ringlock Ledger

With Wedge connection head at both ends, used in different lengths as support for ledger decks of standard scaffold planks as well as guard rails and to reinforced the scaffold

|

Length/M (Euro Type) |

Length (in foot) |

Material |

Surface |

|

|

0.73m |

2’ |

48.3*3.2mm |

H.D.G |

|

|

0.9m |

1.09m |

3’ |

||

|

1.2m |

1.29m |

4’ |

||

|

1.5m |

1.4m |

5’ |

||

|

1.8m |

1.57m |

6’ |

||

|

2.1m |

2.07m |

7’ |

||

|

2.4m |

2.57m |

8’ |

||

|

2.7m |

3.07m |

10’ |

Ringlock Standard

|

Length |

Material |

Surface |

|

0.5m |

48.3*3.2mm |

H.D.G |

|

1.0m |

||

|

1.5m |

||

|

2.0m |

||

|

2.5m |

||

|

3.0m |

Ringlock Bridging Ledger

Designed to support scaffold decks if large bay areas are required, alternatively to support scaffold in case of spanning obstructions

|

Length/M (Euro Type) |

Length (in foot) |

|

|

1.5m |

1.4m |

5’(1524mm) |

|

1.8m |

1.57m |

6’(1829mm) |

|

2.1m |

2.07m |

7’(2134mm) |

|

2.4m |

2.57m |

8’(2438mm) |

|

2.7m |

3.07m |

10’(3048mm) |

Ringlock Truss Beam

|

Length/M (Sino Type) |

Length/M (Euro Type) |

Length (in foot) |

|

4.8m |

|

16’(4876mm) |

|

5.4m |

|

20’(6096mm) |

|

7.2m |

|

21’(6402mm) |

Ringlock Vertical Diagonal Brace

Wedge lock principle for positive and non-positive connections, without screwed connections, for bracing the basic scaffold

|

Length/M(Sino Type) |

Length/M(Euro Type) |

Length(in foot) |

|

H2.0L0.73m |

||

|

H2.0L0.9m |

H2.0L1.09m |

H2.0L3’(914mm) |

|

H2.0L1.2m |

H2.0L1.29m |

H2.0L4’(1219mm) |

|

H2.0L1.5m |

H2.0L1.4m |

H2.0L5’(1524mm) |

|

H2.0L1.8m |

H2.0L1.57m |

H2.0L6’(1829mm) |

|

H2.0L2.1m |

H2.0L2.07m |

H2.0L7’(2134mm) |

|

H2.0L2.4m |

H2.0L2.57m |

H2.0L8’(2438mm) |

|

H2.0L2.7m |

H2.0L3.07m |

H2.0L10’(3048mm) |

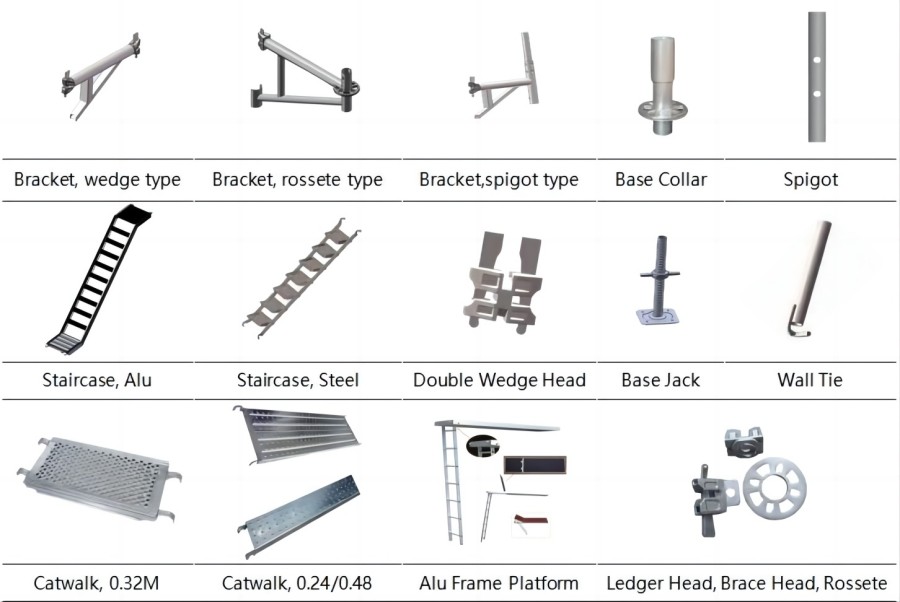

Ringlock Accessories

Product Photos

Quality and Responsibility is more than a priority !

Any inquries & questions, please contact Onward Indusrty Co., Ltd. at any time. Email: info@csonward.com

Scaffolding tubes, crafted from robust galvanised steel, serve as the backbone of temporary platforms in construction, renovation, and maintenance endeavors. These sturdy metal poles are engineered for durability, capable of supporting substantial weights. Available in a range of pre-cut lengths, they offer the versatility needed to tailor scaffolding to the unique requirements of any project. For more insights on how to utilize scaffolding tubes both effectively and safely, be sure to explore our informative blog.

Portal scaffold

Common specifications and dimensions include: 1220 × 914 millimeters, 1220 × 1524 millimeters, 1220 × 490 millimeters, 1265 × 1930 millimeters, 1219 × 1700 millimeters, 1219 × 1930 millimeters, etc.

Ladder scaffold

Common specifications and sizes include: 1700 × 914 millimeters, 1219 × 1930 millimeters, 1219 × 1700 millimeters, etc.

Half frame scaffolding

Common specifications and sizes include: 914 × 914 millimeters, 1219 × 914 millimeters, 1219 × 1219 millimeters, etc.

Mobile scaffolding

Common specifications and dimensions include: 1900 × 1250 × 1800mm, 1700 × 950 × 1800mm, 1000 × 950 × 1800mm, etc.

Buckle type scaffolding

The diameter of the pole is generally 48 millimeters or 60 millimeters, with various lengths such as 0.3 meters, 0.9 meters, 1.2 meters, 1.8 meters, 2.1 meters, 3 meters, etc.

The specification module of the crossbar model is 300 millimeters: conventional sizes include 300 millimeters, 600 millimeters, 900 millimeters (actual length is about 850 millimeters), 1200 millimeters, 1500 millimeters, 1800 millimeters, etc.

Our scaffolding tubes are made of high-quality galvanised steel.The galvanisation process coats the steel with a protective layer of zinc.This zinc coating acts as a shield against rust and corrosion, making galvanised steel tubes ideal for withstanding harsh weather conditions often encountered on construction sites.This ensures the long-lasting performance and safety of your scaffolding throughout your project.

Scaffolding poles serve as the core element of temporary frameworks, enabling access to elevated areas and bearing loads in construction, renovation, and maintenance tasks. They offer a secure platform for both workers and materials. To learn more, visit our informative blog.

Sturdy and Durable: Crafted from high-quality galvanized steel, our scaffolding platforms provide a robust foundation for workers and materials. The galvanization process shields against rust and corrosion, ensuring long-term durability for outdoor use.

Adaptable and Customizable: With pre-cut lengths and a range of customization options, our scaffolding can be tailored to fit around any structure, offering safe and easy access to every area.

Efficient and Time-Saving: Standardized diameters and user-friendly couplers facilitate quick assembly and dismantling, reducing downtime and boosting productivity on the job site.

Cost-Effective Solution: The reusability of our scaffolding tubes across multiple projects makes them a wise investment. The initial purchase cost is quickly offset by the savings compared to renting temporary structures.

Versatile and Multipurpose: In addition to construction, our scaffolding tubes can be used to create temporary event structures, support signage and lighting, and provide a sturdy base for various maintenance tasks.

For a deeper dive into the advantages of scaffolding, be sure to check out our informative blog.

Our factory in China boasts over 20 production lines, encompassing a wide range of products including scaffolding tube,Scaffolding Couplers,Scaffolding Couplers,Adjustable Steel Prop,frame scaffolding system etc.With our advantageous pricing as a Chinese manufacturer, we are able to offer cost-effective solutions without compromising on quality.Coupled with our efficient production processes, we ensure prompt delivery to support our clients with consistent quality and timely service.The monthly production capacity of our factory stands at around 8000 tons, further enhancing our ability to meet client demands swiftly and reliably.